Sumitomo Rubber Industries, Ltd. (CEO: Satoru Yamamoto) is pleased to announce that we have joined GDSO (the Global Data Service Organisation for Tyres and Automotive Components), an international NPA working to standardize data related to tires and define solutions for accessing and exchanging tire data. The tire industry as a whole has been working to establish individual tire identification and management to achieve data transfer starting from truck and bus tires. As a member of GDSO from January 2023, the Sumitomo Rubber Group will be working to further these efforts while aligning with industry standards.

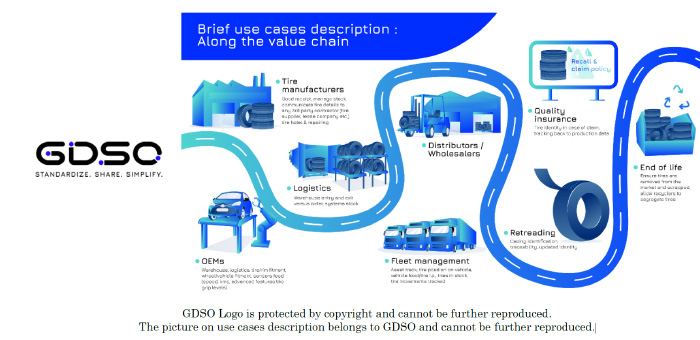

GDSO built a platform, the Tire Information Service (TIS) to allow the transfer of data related to tires enabled with a Unique Item Identifier (UII). While actively participating in these and other efforts to establish industry standards, the Sumitomo Rubber Group will also be constructing a database so that users can access data on the tires that we manufacture and sell using RFID*1 technology.

RFID is a wireless communication technology that uses radio waves for individual identification instead of conventional barcodes or QR codes. Applied to tires, RFID systems can be used for individual identification and management toward achieving traceability, which will allow for significant improvements in terms of quality control, responding to customer claims, eliminating counterfeit tires and more. In addition, this technology also has the potential to contribute to greater operational efficiency and safety by simplifying warehouse inventory management and making it easier to check when tires were manufactured, mounted on vehicles, serviced and more.

In the future, we hope to utilize RFID technology for extensive analysis of tire data so that we may provide service with greater added value in order to better meet the needs of our customers through retreading*2, maintenance and other services that we will provide as part of our Solutions Business.

In August 2021, the Sumitomo Rubber Group unveiled our Long-Term Sustainability Policy: “Driving Our Future Challenge 2050.” Toward accomplishing our sustainability challenge for the future, we are currently working to find solutions to various issues when it comes to the global environment, coexisting with society and corporate governance. In order to adeptly respond to what is being called a once-in-a-century transformation of Mobility Society, we will continue working to accelerate the development of safe, environmentally friendly and sustainable tires with a renewed focus on LCA (Life Cycle Assessment) while also taking full advantage of RFID and other forms of DX (Digital Transformation) to “Reduce CO2 Emissions,” “Transition to Biomass & Recycled Raw Materials” and “Engage in Sustainable Product Development” throughout our value chain: from procurement to transportation, development to manufacture, sales to usage and ultimate disposal.

※ that uses radio waves to transmit and receive

data.

※2. Retreading refers to a process for recycling worn out tires by removing the spent tread and then applying new tread rubber to the tire casing.