Sumitomo Rubber Industries (SRI) has announced the results of the joint research with the Leibniz Institute for Polymer Research into the mechanisms behind rubber failure. This ground-breaking research has shed light on the previously unknown mechanism that causes the microscopic voids that form within rubber (presumed origin of rubber failure) to develop into cracks in the rubber itself.

These findings open up new possibilities for the future development of rubber compounds that feature greater wear resistance than any type of rubber that has come before. SRI will continue working to translate the results of their cutting-edge research into high-performance tyres that resist wear to maintain their performance for longer.

With the automotive industry currently facing many sweeping changes, Sumitomo Rubber Industries has responded by formulating their Smart Tyre Concept; a new tyre technology that aims to achieve ‘even greater safety performance’ and ‘even greater environmental performance’.

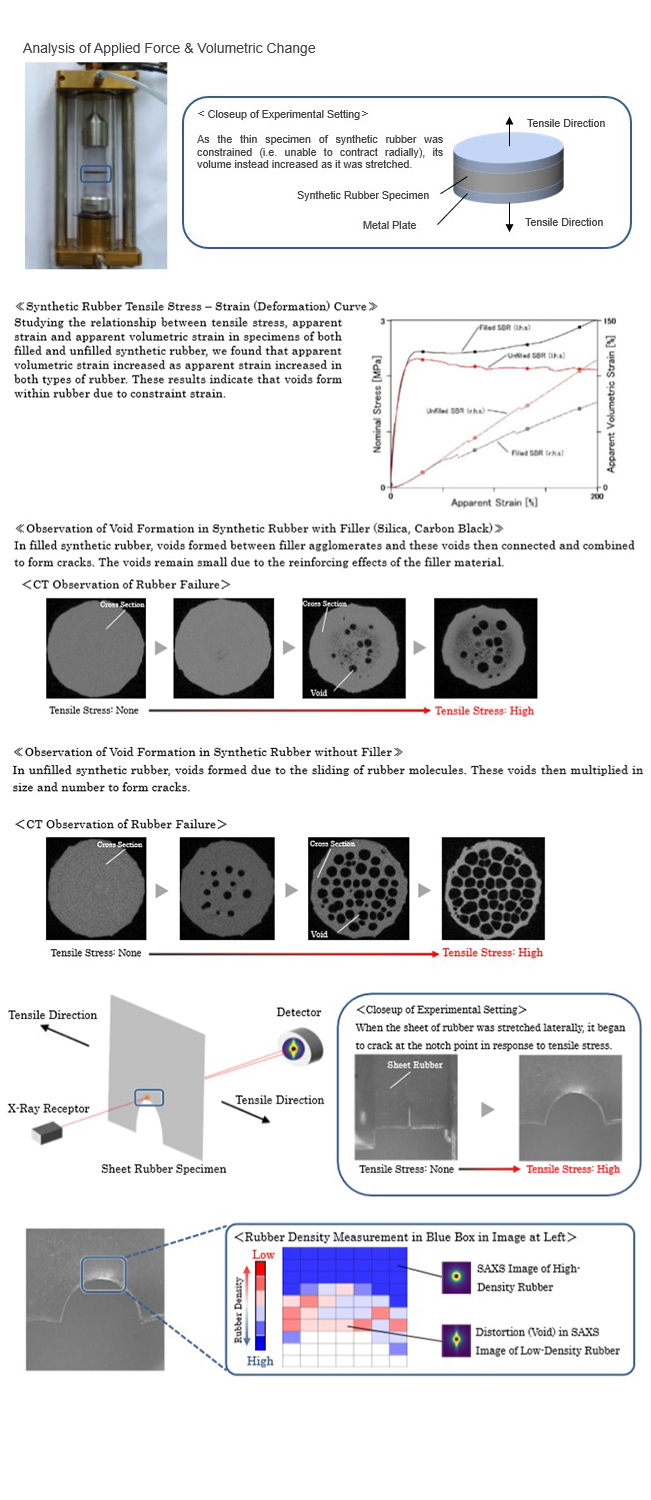

The results of this recent joint research will contribute to one of the major development themes of the smart tyre concept: ‘Performance Sustaining Technology’ for tyres. While it has long been suspected that rubber failure (one of the major factors behind tyre wear) is due to the formation and growth of cracks in the rubber resulting from the fracturing of rubber molecules and the formation of voids within rubber at the microscopic scale, previous research had failed to fully validate this theory.

Thus, SRI set out to observe the formation of voids in synthetic rubber. In 2015, SRI succeeded in shedding light on the formation of voids thanks to detailed molecular-level structural simulations that utilised their proprietary Advanced 4D Nano Design technology, which has allowed SRI to establish new technologies to suppress void formation.

With this latest joint research, SRI has succeeded in directly observing internal structural changes in combination with the mechanical behaviour of molecules within actual synthetic rubber specimens through two different types of experiments. The findings of this research will open up new possibilities for the development of rubber materials with extremely high durability by giving greater control over viscoelastic properties of the rubber itself.